In the News

Case Study: American Airlines Goes Green with NexSys PURE

A pioneer in electrification of ground support equipment (GSE), American Airlines started a push for battery-powered ramp vehicles in 1996. Today, the carrier remains committed to converting from internal combustion vehicles to electric vehicles to reduce expenses and lower emissions. American’s commitment to going electric now includes experimentation with advanced battery technologies that can cut costs further and have a greater environmental impact over conventional lead-acid batteries.

In 2016, American faced chronic battery failures in its bag tractors at DFW. They were facing multiple factors including the Dallas heat, increased duty cycle, difficulty in keeping up with watering maintenance, and challenges with getting the ramp to plug in to the chargers. Station Manager Antonello Davi states, “The ramp became addicted to the fast chargers. They would let the batteries die because they knew they could get a quick bump in power to go another 15 minutes. The batteries would never get fully charged.”

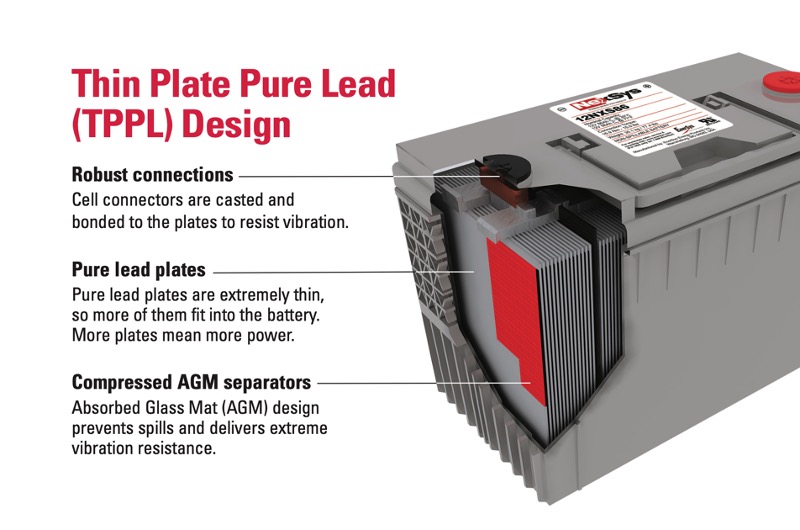

The lead-acid batteries were failing in as little as two to three years. Needing a more robust battery solution, American tested a technology that had proven successful in other American applications as well as other carriers – thin plate pure lead (TPPL) NexSys PURE batteries from EnerSys. As a result, the carrier ultimately found a battery that could last as long as five to six years.

The Benefits of TPPL Technology for GSE

Developed for military use in the 1970s, TPPL technology offers several benefits for GSE applications. Unlike flooded lead acid batteries, TPPL batteries are sealed and never require watering. This feature eliminates the associated maintenance hours and the risk of hazardous acid spills, along with the hassle of reporting these spills to airport environmental offices.

TPPL batteries also withstand shock, vibration and extreme temperatures. They have extremely fast charge rates and can be opportunity-charged during breaks and in- between flights with no risk of damage. In fact, TPPL batteries offer a maintenance and charging footprint that is similar to lithium-ion batteries while delivering excellent cycle life with a favorable total cost of ownership.

A Baggage Tractor Trial

Working with Allen Energy, the EnerSys representative, the DFW GSE shop used several demo NexSys batteries to optimize the controller setting in the tractors. The trial proved that the NexSys PURE batteries provided an immediate increase in productivity. They were in use more, and on charge less, providing the ramp more availability and utilization of their tractors. The trial also produced a year of operating data showing that the NexSys PURE batteries could exceed three years of life.

As a result, Joe Girting, American’s GSE fleet manager, made NexSys PURE the airline’s official battery for DFW and other critical stations.

“Specifying thin plate pure lead batteries for our baggage tractors makes sense financially and environmentally,” Girting says. “The NexSys PURE battery eliminates the cost of replacing batteries prematurely and eliminates the risk of spills. Plus, we’re experiencing improved performance. All things considered, going with the NexSys PURE battery is an obvious choice.”

Performance Data Comparison

Flooded Batteries:

Max Daily Discharge (kwh): 19

Ave Daily Discharge (kwh): 12

Ave Drive Time (min): 95

Ave Daily Charge Time (min): 242

NexSys PURE Batteries:

Max Daily Discharge (kwh): 20

Ave Daily Discharge (kwh): 13

Ave Drive Time (min): 116

Ave Daily Charge Time (min): 225

TPPL Success in Service

Today, American’s decision to use NexSys has proven to be even more beneficial for the airline. Since 2016, they have replaced hundreds of lead-acid batteries in stations around the country including major HUBs like LAX, PHL, and CLT. According to Todd Allen, president of Allen Energy, the battery life is exceeding five years. Allen states that data captured from the DFW NexSys batteries in August 2021 show that the batteries are maintaining good condition throughout their life. “Even batteries installed in 2016 have more life left in them.”

American Airlines intends to keep looking for GSE applications that will benefit from advanced battery technologies like TPPL. Procurement Manager, Sean Deangelis, states, “we’re looking at the benefits of NexSys in all our equipment including maintenance carts and terminal carts. We’re also seeing benefits from the Odyssey TPPL battery for starter applications.”

“Thin plate pure lead technology aligns perfectly with our corporate commitment to purchase equipment with lower emissions, and with our ongoing efforts to optimize our operations and operating costs,” Deangelis says.

Lifecycle Battery Costs and Savings

Flooded Batteries:

$3,000 (purchase) + $100 (repairs) + $300 (maintenance) = $3,400 per year

x 5 = $17,000 per tractor (5 year cost)

x 80 tractors = $1,360,000 total

NexSys PURE Batteries:

$2,000 (purchase) + $100 (repairs) = $2,100 per year

x 5 = $10,500 per tractor (5 year cost)

x 80 Tractors = $840,000 total

Total Five-Year Savings: $520,000

Contact Us

Allen Energy, Inc.

8815 Conroy Windermere Road #223

Orlando, Florida 32835 USA

+1 (407) 240-0909