In the News

Case Study: TPPL Batteries Bolster American’s eGSE

Seeking a longer lifespan from its fleet of electric burden carriers, American Airlines found its solution after trialing thin plate pure lead technology

A pioneer in electrification of ground support equipment (GSE), American Airlines started a push for battery-powered ramp vehicles in 1996. Today, the carrier remains committed to converting from internal combustion vehicles to electric vehicles to reduce expenses and lower emissions. American’s commitment to going electric now includes experimentation with advanced battery technologies that can cut costs further and have a greater environmental impact over conventional lead acid batteries.

In 2015, American faced chronic battery failures in its electric burden carrier fleet. The vehicles were serving as both personnel carriers in the terminal and maintenance carts on the ramp.

The lead acid batteries powering them were failing in less than a year – often in as little as six to nine months. Needing a more robust battery solution, American tested a technology that had proven successful in its baggage tractors – thin plate pure lead (TPPL) NexSys PURE batteries from EnerSys.

As a result, the carrier ultimately found a battery that could last as long as four to six years.

The Benefits of TPPL Technology for GSE

Developed for military use in the 1970s, TPPL technology offers several benefits for GSE applications. Unlike flooded lead acid batteries, TPPL batteries are sealed and never require watering. This feature eliminates the associated maintenance hours and the risk of hazardous acid spills, along with the hassle of reporting these spills to airport environmental offices.

TPPL batteries also withstand shock, vibration and extreme temperatures. They have extremely fast charge rates and can be opportunity-charged during breaks and in-between flights with no risk of damage. In fact, TPPL batteries offer a maintenance and charging footprint that is similar to lithium-ion batteries while delivering excellent cycle life with a favorable total cost of ownership.

A Terminal Cart Trial

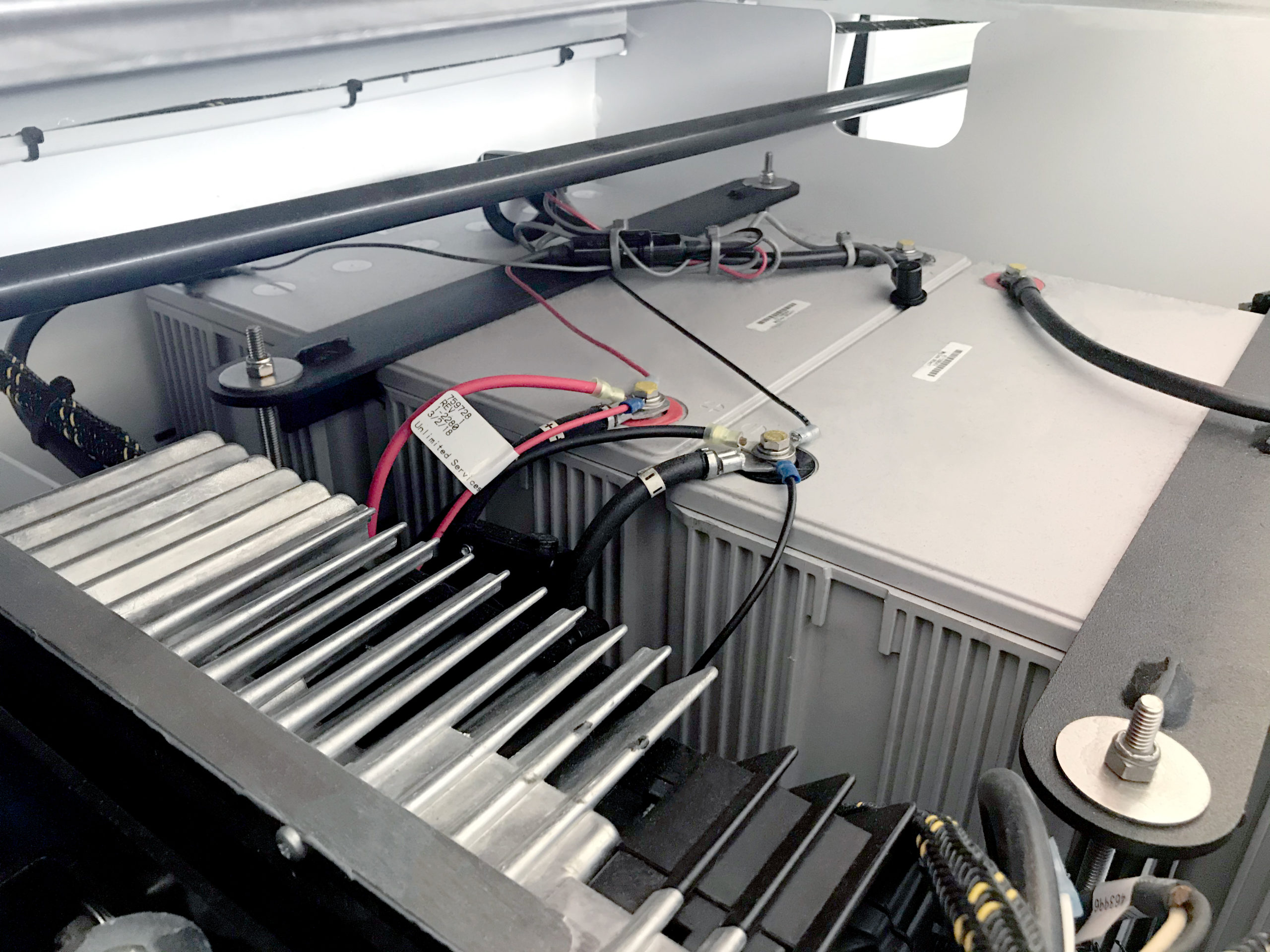

Working with Allen Energy, the EnerSys representative, and Columbia Vehicle Group Inc., the burden carrier manufacturer, American initiated a TPPL battery trial at Charlotte Douglas International Airport. For the trial, two Columbia burden carriers were each outfitted with four NexSys PURE TPPL 12-volt batteries. From May 2015 to May 2016, the carriers were used to ferry passengers around the terminal, and the batteries ran as promised, with no issues or unexpected downtime.

In addition to running past the one-year mark and outlasting the previously used conventional batteries, the trial also produced a year of operating data showing that the NexSys PURE batteries could exceed three years of life. As a result, Joe Girting, American’s GSE fleet manager, made NexSys PURE the airline’s official battery for all new burden carriers.

“Specifying thin plate pure lead batteries for our new burden carriers made sense financially and environmentally,” Girting says. “The NexSys PURE batteries eliminate the cost of replacing batteries in a year or less and eliminate the risk of spills. Plus, the data suggested that they would last three years or more. All things considered, going with the NexSys PURE battery was an obvious choice.”

TPPL Success in Service

Today, Girting’s decision has proven to be even more beneficial for the airline. In 2018, American purchased a new fleet of more than 30 Columbia burden carriers outfitted with the NexSys PURE TPPL batteries. According to operating data captured in April 2020, the batteries are on track to substantially exceed their 36-month warranty. The data shows an expected service life for this fleet to be between four and six years.

According to Todd Allen, president of Allen Energy, it may be even longer than that. Allen states that EnerSys recently downloaded data from NexSys PURE batteries installed in an American maintenance cart burden carrier at Pittsburgh International Airport. These batteries were installed in 2015, at roughly the same time as the initial trial at Charlotte.

“At about 60 months in, the batteries have only used about half of their available throughput in amp-hours. As they did in the Charlotte trial, these TPPL batteries have far exceeded the life of conventional batteries,” says Allen. “They are delivering an exceptional long-term value for American – one that any carrier can benefit from, as the NexSys PURE batteries are also available in kits to retrofit them to any existing electric burden carrier.”

American Airlines intends to keep looking for GSE applications that will benefit from advanced battery technologies like TPPL.

“Thin plate pure lead technology aligns perfectly with our corporate commitment to purchase equipment with lower emissions, and with our ongoing efforts to optimize our operations and operating costs,” Girting says.

Contact Us

Allen Energy, Inc.

8815 Conroy Windermere Road #223

Orlando, Florida 32835 USA

+1 (407) 240-0909